PEC offers a wide range of cell testers, starting from the 5A desktop test system (ACT0505), to our range of 50A cell testers for more standardized cycling (CT0550) and our advanced cell testers with capabilities up to 4000A (ACT0550). All systems support parallel switching for achieving higher currents.

ACT0505

5A Desktop Cell Tester

Preparing a test can be done off-line on an existing desktop PC, running our LifeTest™ application. The End User can configure the specific test by means of an Event Table. The PC communicates with the Battery Tester over Ethernet to load the test conditions and upload the measurement data.

Every channel is independent, microprocessor controlled and uses a POWER MOSFET to obtain a very high accuracy, reliability and flexibility. 10 channels of 5V, 5A are mounted in 1 desktop unit.

The system comes standard with 3 current ranges, that are automatically switched. Optionally, you can add analog and digital in- and outputs to the system via the auxiliary I/O modules of 8 slots each (e.g. temperature sensors, voltage inputs, pressure sensors, digital output, …)

The system supports current, voltage, power and resistive based loads, with a minimum pulsing width of 1 msec. Our ACT0505 system will give you ultra fast switching capabilities between charging and discharging modes, guaranteeing you the accuracy you need.

ACT0550

High Power Equipment for Cells

Preparing a test can be done off-line on an existing desktop PC, running our LifeTest™ application. The end user can configure the specific test by means of an event table. The PC communicates with the cell tester over Ethernet to load the test conditions and upload the measurement data.

FPGA controller per channel for real time current and voltage control. The channels use a POWER MOSFET to obtain a very high accuracy, reliability and flexibility. 80 channels of 5V, 50A are mounted in 1 test rack.

The system comes standard with 4 current ranges, that are automatically switched. Optionally, you can add analog and digital in- and outputs to the system via the auxiliary I/O modules of 8 slots each (e.g. temperature sensors, voltage inputs, pressure sensors, digital output, …)

The system supports current, voltage, power and resistive based loads, with a minimum pulsing width of 1 msec. Our ACT0550 system will give you ultra-fast switching capabilities between charging and discharging modes, guaranteeing the accuracy you need.

CT0550

High Power Equipment for Cells

Preparing a test can be done off-line on an existing desktop PC, running our LifeTest™ application. The End User can configure the specific test by means of an Event Table. The PC communicates with the Battery Tester over Ethernet to load the test conditions and upload the measurement data. Every channel is independent and uses a POWER MOSFET to obtain a very high accuracy, reliability and flexibility. 80 independent channels of 5V, 50A are mounted in 1 test rack. Channels can be paralleled to a max of 1000 AMPS.

The system comes standard with 2 current ranges, that are automatically switched. Optionally, you can add analog and digital in- and outputs to the system via the auxiliary I/O modules of 8 slots each (e.g. temperature sensors, voltage inputs, pressure sensors, digital output, …)

The system supports current, voltage, power and resistive based loads, with a minimum pulsing width of 10 msec. Our CT0550 system will give you ultra fast switching capabilities between charging and discharging modes, guaranteeing you the accuracy you need.

CT0510

For High Volume Cell Testing

The CT0510 is a 1024-channel regenerative cell tester, ideal for high volume testing multi-layer pouch cells, 18650, 21700 or 46XXX cells in cell development and QC labs. This test equipment can be used in several areas, from cell formation to quality control and lifecycle testing.

Preparing a test can be done off-line on a PC or Laptop, running our LifeTest™ application. The end user can configure specific test profiles with cell dependent parameters. The LifeTest™ application communicates with the cell tester over Ethernet to load the test conditions and upload the measurement data.

Due to the high-volume architecture tests are started per test board of 8 cells. Although the Test Regimes are common for the board, channels are controlled individually.

The channels use Regenerative Power Supplies to obtain a very high Channel Density. 1024 channels of 5V, 10A are mounted in 1 test rack. Optionally, you can add analog and digital in-and-outputs to the system using the PEC auxiliary I/O modules (e.g. temperature sensors, voltage inputs, pressure sensors, digital output etc.)

The system supports current, voltage, power and resistive based loads, with a minimum pulsing width of 10 msec. Our CT0510 system will give you ultra-fast switching capabilities between charging and discharging modes, guaranteeing the accurate simulations you need.

CT0501 Cell Test System

The CT0501 is a 1024-channel low power cell tester, ideal for high volume testing R&D coin cells, single layer pouch or 18650 cells in cell development and QC labs. This test equipment can be used in several areas, from cell formation to quality control and lifecycle testing.

Preparing a test can be done off-line on a PC or Laptop, running our LifeTest™ application. The end user can configure specific test profiles with cell dependent parameters. The LifeTest™ application communicates with the cell tester over Ethernet to load the test conditions and upload the measurement data.

Due to the high-volume architecture tests are started per test board of 8 cells. Although the Test Regimes are common for the board, channels are controlled individually.

The channels use Linear Power Mosfets to obtain a very high accuracy and speed. 1024 channels of 5V, 500mA are mounted in 1 test rack.

The system comes standard with 3 selectable current ranges to fit the current requirements of the cells to be tested. Optionally, you can add analog and digital in-and-outputs to the system using the PEC auxiliary I/O modules (e.g. temperature sensors, voltage inputs, pressure sensors, digital output etc.)

The system supports current, voltage, power and resistive based loads, with a minimum pulsing width of 10 msec. Our CT0501 system will give you ultra-fast switching capabilities between charging and discharging modes, guaranteeing the accurate simulations you need.

BDT1012

Primary Test Equipment

The test equipment can be used in several areas, from Research & Development to production Quality Control and incoming goods inspection.By adding more testers in a fieldbus (CAN) network, the number of channels can easily be expanded.

This system is able to test simultaneously and independently more than 5.000 batteries per controller.

Easy Test Setup

Preparing a test can be done off-line on an existing desktop PC, using a graphical user interface. The end-user can define the specific test by means of an Event Table. The PC communicates with the Battery Tester over the CAN network interface to load the test conditions and upload the measurement data.

Every unit of 24 channels works fully independently. It is microprocessor-controlled and uses a dynamic electronic load to obtain a very high accuracy, reliability and flexibility.

Each channel has its own programmable discharge-profile. This profile is a composition of several events. Every event consists of a time interval, a type of load and a value. The load is a constant or intermittent current, resistance or power. With this test system, it is possible to perform pulses of 10 msec! This means typical continuous or intermittent lifecycle and application tests can be performed (toys, pagers, pc…).

This Battery Discharge Test System is designed according to the latest standards in electronics and informatics. Data-integrity is always guaranteed during a power-failure, network or pc-controller breakdown.

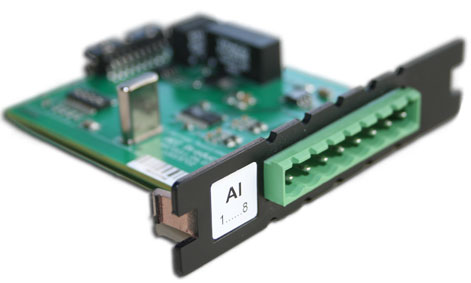

Auxiliary Input and Output Systems (AIO’s)

Auxiliary Input and Output Systems (AIOS) obtain additional data such as individual cell temperatures or individual cell voltages, read digital inputs and control analog & digital outputs. Data received from these sensors are sent to the SBTXX50 via CAN communication. This data can be used in the test program as triggers or end conditions.

Configuration

Each AIOS backplane has 8 slots which can be equipped with different I/O modules. These I/O modules are pluggable and fit in one of the eight slots of the AIOS. Different AIOS backplanes can be connected through daisy-chain with the internal CANbus of the SBTXX50. Up to 1000 aux I/O’s can be controlled by one SBTXX50.

When connected to the internal CANbus of the SBTXX50, the Lifetest Software allows a flexible mapping of the I/O modules to each channel of the SBTXX50. The AIOS can also be connected to the CANbus interface of an individual channel. The sampling time of the modules is then increased from 1 second to 100 msec. The possible configurations can be found on the backside of this document.

Different IO’s

The AIOS backplane supports 6 types of I/O-modules: analog voltage input, analog voltage ouput, digital input, digital output and temperature sensor input (RTD modules for thermistors and THC modules for thermocouples). Technical specifications of these modules can be found on the backside of this document.