Cell Testing

Providing a wide range of 500mA to 50A cell testers featuring parallel switching up to 4000A.

Lab Automation

Automating operations in high volume test fields by integrating instrumentation, climate chambers and cell holders in a single solution.

Lab Management Software

One-stop software for supporting the test planning, execution and data analysis, perfectly complimenting PEC’s Cell Test Equipment.

From µA to 4000A

PEC offers cell and module testers ranging from low power desktop and rack mount cell testers all the way up to high power test systems for cells and modules. All systems are based on linear technology offering excellent dynamics and precision. Systems are typically used in R&D, product evaluation, life cycle testing and end-of-line testing.

Drive Cycle Testing

The software allows end users to download and run pre-recorded CSV files on the test channels. This way the system can simulate complex load patterns found in xEV applications, smart grids…

Climate Chamber Control

Most commonly used climate chambers in the battery industry are directly controlled from the test channels, not requiring any third party software interface.

No Heat, no Noise in the Lab

A major challenge in high power test systems is the thermal management of the equipment. Over the years PEC has used its vast experience in water-cooled power electronics to eliminate all unnecessary fans and implement an internal cooling system for the power electronics. This innovative cooling technique was introduced a few years ago in PEC’s cell formation towers. The same platform has now been standardized at PEC and will be used as the basis for all new PEC test systems. As an immediate effect of this high performance cooling platform the test systems will turn your cell testing lab back into area without heat and noise pollution. The improved cooling and elimination of external fans easily doubles the MTBF of the equipment, eliminates filter replacement and dust collection inside the power electronics.

Precision and Speed

In terms of precision and speed PEC has raised the bar on its latest product releases, with 100 µsec based internal sampling, control and capacity calculations, hardware controls for both current and voltage* and a ± 0.005% FSD accuracy on the voltage readings*. All PEC systems have best-in-class features on board, such as 2, 3 or 4 automatically switched current ranges, ±0.03% FSD current control, better than 1 msec rise times, including range and mode switching transitions… * On specific models only

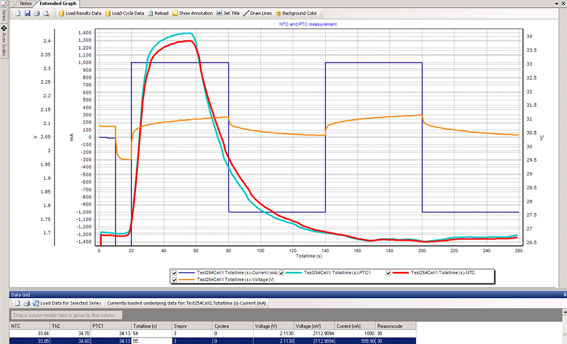

Auxiliary Measurements

Most PEC systems offer an onboard temperature sensor per test channel. However this can easily be extended using our Auxiliary IO’s, offering analog and digital inputs, outputs, thermocouple inputs, NTC/PTC inputs, as well as BMS interface cards. All data collected from the IO’s can be used in your test programs, and outputs can also be set from the software.

Electrochemical Impedance Spectroscopy (EIS) Integration

Specific PEC Cell Testers can be optionally extended with selected third party EIS instrumentation for measuring Cell Impedance. The EIS device is connected to the cell in parallel with the PEC test system and allows for EIS measurements to be scheduled and parametrized in the PEC test regime.

The EIS instrument is then controlled by the PEC Cell Tester. The measurement data from the EIS instrument is saved together with the rest of the test results in PEC’s LifeTest Database. The researchers will use PEC’s LifeTest software to analyze the results using e.g. Nyquist and Bode Plots.