Module Testing

This product range offers 45V, 100V and 150V systems, with a 60A per channel capability. All systems support parallel switching for achieving higher currents. Each channel has an onboard CAN-bus connection for BMS interfacing and can be extended with auxiliary IO’s for single cell voltage and temperature measurements.

SBT4560

High Power Equipment for Batteries

The SBT4560 is a 16-Channel Battery Tester, ideal for testing and evaluating HEV as well as industrial battery modules and packs. Our equipment is designed for both laboratory and production scale applications, including formation and ranking.

By adding more test channels to the master controller and more test systems to the same network, the number of channels can easily be expanded.

Preparing a test can be done off-line on an existing desktop PC, running our LifeTest™ application. The End User can configure the specific test by filling out the Event Table with the individual cycle steps. For complex or HEV cycles, the software allows a direct import to the events through a preformatted CSV file.

The system supports current, voltage, power and resistive based loads, with a minimum pulsing width of 1 msec. Our SBT4560 system will give you ultra fast switching capabilities between charging and discharging modes, guaranteeing you the accuracy you need.

Every channel is independent, microprocessor-controlled and features a dynamic electronic load to obtain very high accuracy, reliability and flexibility. Using a CANbus or SMbus interface the unit can communicate with the battery module or pack to obtain additional data, such as the individual cell voltages and temperatures.

The power MOSFETS are mounted on a central liquid cooled heatsink which will evacuate the discharging heat to a central heat exchanger.

SBT10060

High Power Equipment for Batteries

The SBT10060 is a 16-Channel Battery Tester, ideal for testing and evaluating HEV as well as industrial battery modules and packs. Our equipment is designed for both laboratory and production scale applications, including formation and ranking.

By adding more test channels to the master controller and more test systems to the same network, the number of channels can easily be expanded.

Preparing a test can be done off-line on an existing desktop PC, running our LifeTest™ application. The End User can configure the specific test by filling out the Event Table with the individual cycle steps. For complex or HEV cycles, the software allows a direct import to the events through a preformatted CSV file.

The system supports current, voltage, power and resistive based loads, with a minimum pulsing width of 1 msec. Our SBT10060 system will give you ultra fast switching capabilities between charging and discharging modes, guaranteeing you the accuracy you need.

Every channel is independent, microprocessor-controlled and features a dynamic electronic load to obtain very high accuracy, reliability and flexibility. Using a CANbus or SMbus interface the unit can communicate with the battery module or pack to obtain additional data, such as the individual cell voltages and temperatures.

The power MOSFETS are mounted on a central liquid cooled heatsink which will evacuate the discharging heat to a central heat exchanger.

SBT15060

High Power Equipment for Batteries

The SBT15060 is a 16-Channel Battery Tester, ideal for testing and evaluating HEV as well as industrial battery modules and packs. Our equipment is designed for both laboratory and production scale applications, including formation and ranking.

By adding more test channels to the master controller and more test systems to the same network, the number of channels can easily be expanded.

Preparing a test can be done off-line on an existing desktop PC, running our LifeTest™ application. The End User can configure the specific test by filling out the Event Table with the individual cycle steps. For complex or HEV cycles, the software allows a direct import to the events through a preformatted CSV file.

The system supports current, voltage, power and resistive based loads, with a minimum pulsing width of 1 msec. Our SBT15060 system will give you ultra fast switching capabilities between charging and discharging modes, guaranteeing you the accuracy you need.

Every channel is independent, microprocessor-controlled and features a dynamic electronic load to obtain very high accuracy, reliability and flexibility. Using a CANbus or SMbus interface the unit can communicate with the battery module or pack to obtain additional data, such as the individual cell voltages and temperatures.

The power MOSFETS are mounted on a central liquid cooled heatsink which will evacuate the discharging heat to a central heat exchanger.

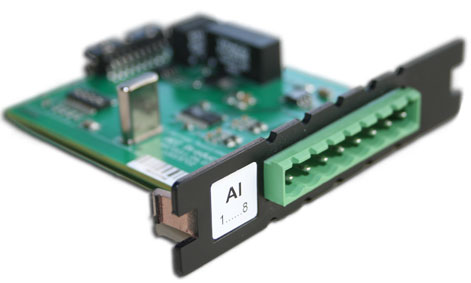

Auxiliary Input and Output Systems (AIO’s)

Product Description

Testing advanced batteries and modules requires more than the usual Battery Voltage, Current and Temperature measurements standard available on the SBTXX60.

Auxiliary Input and Output Systems (AIOS) obtain additional data such as individual cell temperatures or individual cell voltages, read digital inputs and control analog & digital outputs. Data received from these sensors are sent to the SBTXX60 via CAN communication. This data can be used in the test program as triggers or end conditions.

Configuration

Each AIOS backplane has 8 slots which can be equipped with different I/O modules. These I/O modules are pluggable and fit in one of the eight slots of the AIOS. Different AIOS backplanes can be connected through daisy-chain with the internal CANbus of the SBTXX60. Up to 1000 aux I/O’s can be controlled by one SBTXX60.

When connected to the internal CANbus of the SBTXX60, the Lifetest Software allows a flexible mapping of the I/O modules to each channel of the SBTXX60. The AIOS can also be connected to the CANbus interface of an individual channel. The sampling time of the modules is then increased from 1 second to 100 msec. The possible configurations can be found on the backside of this document

Different IO’s

The AIOS backplane supports 6 types of I/O-modules: analog voltage input, analog voltage output, digital input, digital output and temperature sensor input (RTD modules for thermistors and THC modules for thermocouples). Technical specifications of these modules can be found on the backside of this document.